Services

-

Overview

- Supply Chain Management

- Robust R&D for new products & reengineering

- PCBA Manufacturing Capabilities

- System Integration

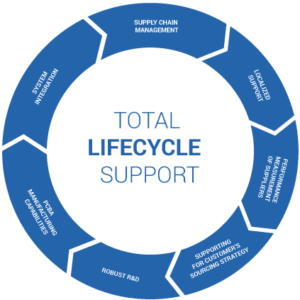

Overview

At Nestronix, we provide complete lifecycle support, based on our customers’ needs.

Supply Chain Management

Nestronix supply chain management philosophy reflects the company’s commitment to deliver services to customers worldwide. The main elements of the supply chain system consist of:

- An efficient system that links customers and suppliers

- A commodity management structure, with an international purchasing office and local staff in different parts of the word

- A computerized replenishment system that allows to that responds to demands in real time

- Stocking plans that meet customer needs

Localized Support

Based on pricing, volumes and demand, Nestronix purchasing teams evaluate the requirement for the best available sourcing.

Performance Measurement of Suppliers

Nestronix continuously measures suppliers based on quality, cost and on-time delivery. Performance is monitored by the production facility that uses the material. We share the feedback with the suppliers either directly or through their purchasing agents. As part of our qualification process, we have an auditing process for vendors that supply fabricated parts.

Supporting for Customer’s Sourcing Strategy

Nestronix works with the supply chain team of its customers to ensure that they get proper credit for materials purchased for them.

Robust R&D for new products & reengineering

Nestronix has access to, through an affiliate company in India, a very robust R&D center which aims at synchronized design between competencies thus ensuring a smooth and hassle free experience for clients. Customers are assisted to establish proof of concept. Not only are new product designs introduced but the reengineering of products which are functionally or technologically obsolete, is also undertaken.

The R&D center works in synergy with manufacturing facilities and provides services like proto type, pilot production and reliability and compliance testing.

The capabilities include

- Electronics and Optronics

- RF & Wireless

- Custom power supplies

- Embedded firmware , FPGA 7 VLSI

- Ergonomic mechanical and enclosure designs

At Nestronix, the value engineering services aims to achieve:

- Functionality improvement and cost reduction.

- Compliance and validation.

- Obsolescence removal and life extension.

- Ergonomics improvements.

PCBA Manufacturing Capabilities

The capabilities of manufacturing facility in India include:

- Low- to high-volume production

- Complex Double-sided Multi-Layer PCBAs

- Leaded and Lead-free

- SMT

- 12m Fine Pitch

- 0201

- 01005

- BGA

- Micro-BGA

- BGA rework

- Through-hole

- Auto Insertion (Axial/Radial/DIP)

- Aqueous cleaning

- Conformal and Parylene coating

- Encapsulation

- Potting

- Test

- AOI

- X-ray laminography

- Flying probe

- Boundary scan

- In-circuit test (ICT)

- Functional Test

- Stress Test

- HOTL/LTOL

- Temp Cycle

- 85/85

- Thermal Shock

System Integration

Nestronix and its affiliate companies have vast experience in complex system-level products, as well as high-end consumer products. Our system integration capabilities include:

- Cable/harness assembly

- Plastic injection molding

- Chassis and electromechanical assembly

- Functional test

- RF/Digital Microwave

- Fiber Optic Test

- Burn-in ESS Testing

- Packaging

- Transformers

- Power supplies